REINVENTING TRADITION

A NEW ICON FOR A NEW AGE

Why must all loudspeakers look like traditional furniture?

Why should they be rectangular boxes?

Why do we put loudspeakers in boxes that don’t naturally work acoustically?

Why must we accept limitations of materials and shape?

Moving into modern materials and techniques liberates the design process, frees the imagination, enables the creation of new natural forms, aesthetics and vision.

ONEIROS™ started officially in late 2023, but we had been looking at the concepts for a long time before then. We decided to break out from tradition, and that high end audio equipment, including loudspeakers, can be both functional and demonstrate genuine aesthetic values.

Long discussions often well into the night were to create an innovative process that enabled us to use genuine composite technologies giving us immersive sonics from a sculptured organic shape.

Ultimately, it would allow us to reach out to our market on a sonic and engaging artistic level.

Slowly, ONEIROS™ changed from dream to have physical presence.

‘why go out on a limb? that’s where the fruit is’

(Mark Twain)

Choice of materials, lateral thinking and access to ground-breaking expertise would be the keys that unlocked ONEIROS™, removing the restraints of the traditions of our industry.

We therefore started to look more closely at our thinking on designs and what we wanted to achieve. After much discussion, we determined that the field of ‘generative design’ was sufficiently advanced to aid in the creation of new concepts that could translate into real-world functional products.

It was not being used to design ONEIROS™, but solely to give us a selection of images with design attributes that could be studied further using ‘natural language generative design. From these, three concept designs were eventually chosen for further analysis. From that select group, there was one with the organic shape we had envisioned, one that we always returned to.

It was not how ONEIROS™ was eventually designed to be, but it possessed the greatest appeal, the best potential qualities for optimal sonics and the design aesthetics we had so desired from the start. So we took our ideas, dreams and the exciting concept design and together with what became TEAM ONEIROS™, we fashioned them into the first true design that would eventually lead to one goal.

The ONEIROS™ speaker that you see before you.

FROM THE BOLDEST CONCEPT

To a breathtaking reality

ONEIROS Audio is based in the centre of Motorsport Valley®, the world-famous Formula 1, Formula E and automotive technology development area in the UK.

This gives ONEIROS Audio local access to companies with engineering technologies, material science knowledge and fabrication skills far in excess of those normally available to loudspeaker manufacturers.

We talked with several local F1 manufacturing companies about producing genuine monocoque carbon composite speaker cabinets.

We jointly explored taking the concept of using the image and the initial design we were creating, whilst retaining the organic shape and precision design detailing that we felt to be essential to create ONEIROS™.

It is almost impossible to produce in wood but, in monocoque carbon fiber form using advanced automotive industry CAD and production systems, ONEIROS™ could and would be realised.

A MEETING OF MINDS

AND UNPARALLELED ABILITIES

A meeting with one of the specialist finishing companies we know started everything moving forward. Companies like this are used by automobile companies and designers to provide exceptional one-roof multi-disciplinary design and implementation skills together with wide-ranging creative abilities.

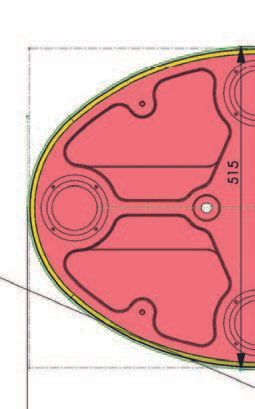

We showed them the concept image together with our evolved design and aesthetics, and discussed transferring all this into a 3D CAD model capable of production. They were eager to help. After 80 hours of intensive CAD design time, the primary design concept emerged. Detailed changes and adjustments to fine tune the design took several more weeks.

In parallel, a Tier 1 company specializing in F1 Finite Element Analysis (FEA) examined cabinet resonances and acoustic properties. The cabinet robustly stood up to this testing, informed what damping we would need, and above all confirmed that the cabinet shape and construction similar to that used in F1 cars would be viable.

Over 100 hours of FEA analysis also enabled us to finalise the composite construction, the various density requirements of the core materials and the thicknesses of carbon fiber we would use. All of this was fed back into the CAD design process.

An in-house designed British manufactured multi-layer inverted parabolic Twaron® graphene nano-composite bass cone, with a profiled neck underneath. 3” voice coil, dual suspension for maximum linear control and stability. The magnet weight alone is 8.2 kgs (18 lbs). The long throw rubber surround gives superb extended bass from the maximum 50mm (2”) pk-pk excursion.

THE INSIDE STORY OF A NEW ICON

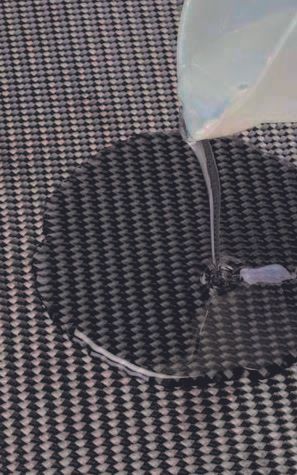

The ONEIROS™ cabinet is a genuine monocoque 100% carbon fibre cabinet. This means that no other materials apart from 2 layers of variable thickness carbon fibre separated by a proprietary profiled high performance foam together with resin is used in the construction. It is an incredibly strong form built in the same way as an F1 car.

INNOVATION & IMAGINATION

CREATED TO PERFORM

ONEIROS™ is created in exactly the same way as the high performance carbon fibre body of an F 1 car, using similar systems. It involves a 3-stage sequence of positive and negative moulds.

The CAD design is first broken down into individual integrated parts that are made into pattern sections in solid polyurethane tooling block. Each pattern is carefully checked to make sure the overall design integrity is maintained. The design allows for easier removal of the subsequent second-stage carbon-fibre tooling parts, which are used as the forms for the third and final component stage, when the actual cabinet parts are created.

The tooling blocks for ONEIROS™ are so big that they require multi-layered blocks to be made up. These are precision machined by sealed chamber, 5-axis CNC cutters that stand about 15’ high. To give an idea of the size and scale of ONEIROS™ construction, there are two main mirrored pattern blocks.

Each half represents one ONEIROS™ body side, is over 4’ long and weighs 250 lbs. They have to be moved by fork-lift trucks. Each pattern section is repeatedly flatted down,checked and hand finished. The surfaces are then sealed and multiple layers of release agent are applied.

Only then can they be used to form the A+ standard tooling that will be used to manufacture the actual cabinet parts. Once the tooling parts are made, the ONEIROS™ pattern blocks are stored and ready for re-use.

AN IMAGINATIVE COMBINATION

OF WORLD-CLASS COMPANIES

All these processes are undertaken by a Tier 1 Formula 1 composite fabricator normally making F1 car parts using Quasi-Isotropic lay-up systems. Strict client confidentiality is always observed.

The variable density cabinet sections are progressively laid up on the tooling, firstly with variable layer(s) of pre-impregnated carbon fibre (pre-preg), then proprietary sandwich material and then more layers of carbon fibre pre-preg.

This is then placed into vacuum bags (-26/-28Hg) to remove any air and consolidate the carbon fiber layers, and then cured in an autoclave at 120C with 3 bar of pressure whilst maintaining the vacuum bag.

Over 2-3 hours the resultant monocoque panels become solid and immensely strong.

WITH A WORLD-CLASS REPUTATION

FOR CRAFTSMANSHIP AND IMAGINATION

The completed cabinet sections are then handed on to our specialist partner cabinet finishing and assembly colleagues. The cabinet sections are bonded together to form a raw ONEIROS™ cabinet.

Damping panels and foam damping precede final finishing, painting or veneering and any sealing lacquer coats. Each pair of ONEIROS™ speakers is custom finished and detailed to the highest level possible with premium materials.

Every layer of paint or lacquer is hand-applied and hand-finished before the next coat is applied. This attention to detail ensures the paint finish is as rich and lustrous as possible before the cabinet built up.

The same specialist partner company normally works with clients such as: F1 teams and prestige automotive manufacturers. These include Rolls-Royce, Bentley, Bugatti, McLaren, Aston Martin and Hennessey (to name but a few we are allowed to).

They also manufacture and finish the precision intricate metalwork detailing that completes ONEIROS™ and makes our ambitious dream a beautiful reality.

SPECIFICATIONS

WOOFERS

2x10” ONEIROS™ in-house designed multi-layer inverted parabolic Twaron® graphene nano-composite bass cones 3” voice coil, dual suspension.

Magnet weight 8.2 kgs (18 lbs).

Cone max. excursion 50mm (2”) pk-pk

MIDRANGE

Twin midrange 3” ONEIROS™ in-house designed Dyneema® graphene composite domes.

Single-layer ribbon CCAW underhung voice coil on Ti former.

Engineered for wide off-axis response.

TWEETERS

1” OEM CVD diamond dome tweeter.

Single-layer ribbon CCAW underhung voice coil on Ti former.

Engineered for wide off-axis response.

CAPACITORS (MF/HF)

Mundorf MCap SUPREME EVO SilverGold.Oil ±3%

CAPACITORS (LF)

Mundorf MCap EVO SilverGold.Oil ±3%

INDUCTORS

Mundorf MCoil CF 70μm copper foil ±2%

RESISTORS

Mundorf MResist ultra HS 30W ±1%

INTERNAL WIRING

Calibration reference grade micro-strand, 651 x 0.07mm OFC copper, TPE CL-free insulation.

DLF tan d -0,003

FREQUENCY RESPONSE (LISTENING AXIS)

20 – 35,000 Hz

POWER RATING

100 W – 750 W

RECOMMENDED AMPLIFIER POWER

Minimum 100 W

NOMINAL IMPEDANCE

4 Ohms. Min. Impedance 2.6 Ohms @ 90 Hz

SENSITIVITY

90 dB/2.83 V

DIMENSIONS

Height: 1610mm (63 ½”), add 65mm (2½”) for spikes.

Width (Max): 575mm (22¾”)

Depth (Max): 760mm (30”)

WEIGHT

140kg (310 lbs)

SHIPPING WEIGHT (PER SPEAKER)

200kg (440 lbs)

SHIPPING DIMENSIONS (PER SPEAKER)

1796 × 746 × 878mm (71” × 29½ × 34½”)

DIMENSIONS